Author: Andrew Jolliffe in: Painting and Coating

Paintline

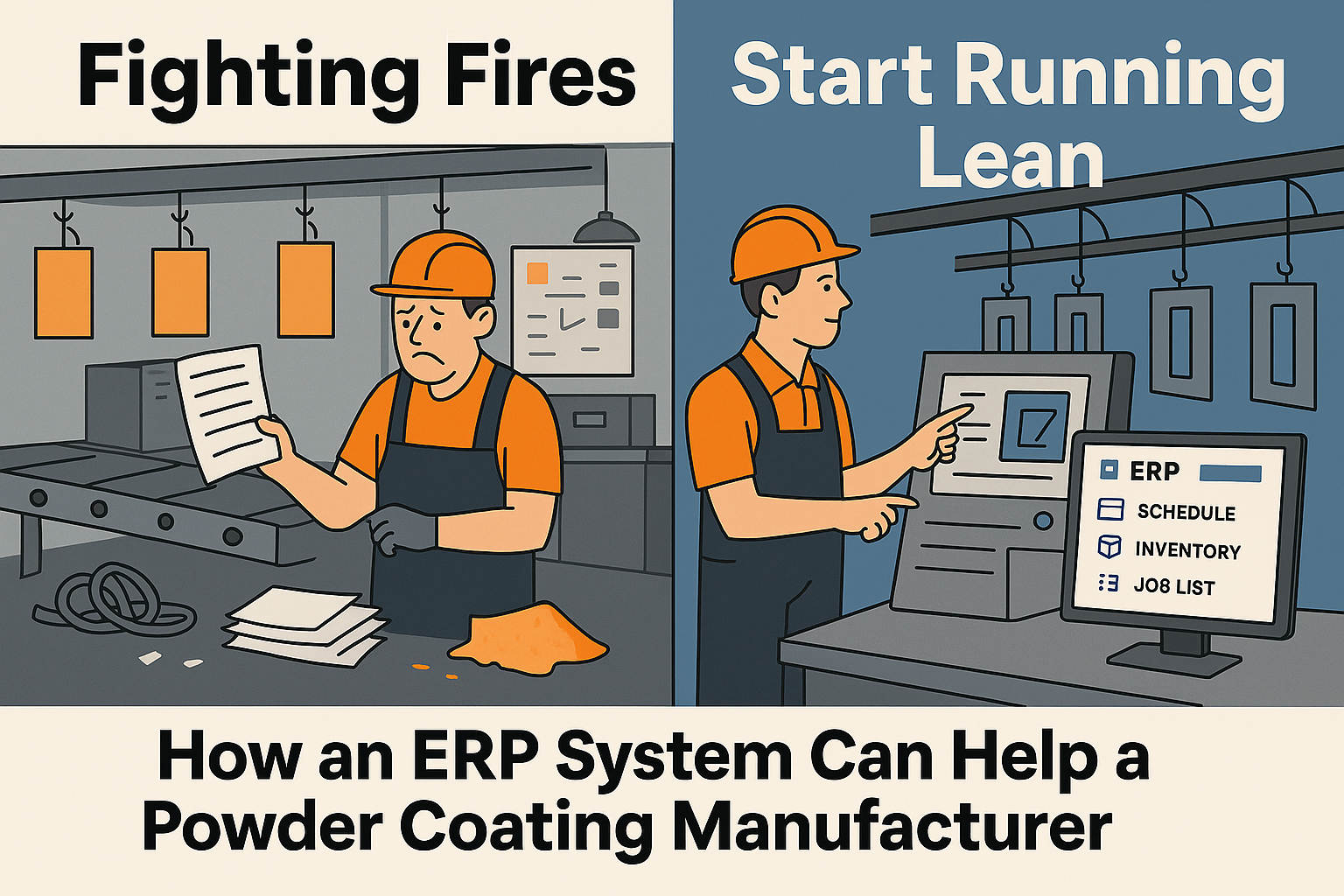

Powder coating facilities are constantly being told that time is always against you, parts need to move faster, and deadlines are tight. When an element of your operation starts to fall behind, the ripple effect can stall your entire production line. Add in poor scheduling, wasted material, and disconnected tools, and you are starting to dig yourself into a cycle of chaos that’s hard to break.

Some small to mid-sized coating manufacturers feel the pains of these situations more frequently than not. You don’t have the luxury of excess labour, or unlimited time. Every misstep costs you money, time and credibility.

It’s time to flip the script.

Let’s be honest, the cost of running inefficiently adds up quickly. It isn’t just inconvenient, it becomes expensive, stressful and unsustainable.

The warning signs are usually there, but they’re buried under paperwork, miscommunication, and disconnected tools. Most organizations don’t see the problem until it’s already cost them money, customers, or both.

A delayed order might seem like a small slip, but to your customers, it’s a breach of trust. Which can cause damaged relations with your customers, or worse the risk of losing the next job all together.

Over spraying, incorrect prep, or rework caused by bad info on the floor cuts straight into your margins, and its often not tracked until it’s too late

When your team isn’t on the same page, jobs get double-handled, misrouted, or rushed through without proper quality control. That creates more scrap, more rework, and more missed deadlines.

If you can’t see what’s happening on the floor, or worse, what’s about to go wrong you are forced into constant damage control. That means more firefighting, less planning, and a team that’s always stretched too thin, and reacting instead of executing.

You can’t scale or run lean with disconnected systems. What’s even worse? A lot of shops are still trying to juggle orders, inventory, and production schedules with spreadsheets, whiteboards, and outdated systems that weren’t built for a growing industry.

Pull out the chaos, and imagine your facility running smoothly, while your team isn’t scrambling, they’re executing. Where deadlines aren’t a moving target, they’re met confidently. Where waste isn’t a hidden cost, its actively minimized. That’s what happens when your operation runs lean and at full power. You can now start to see the light at the end of the tunnel with a modernized purpose-built ERP system.

With a purpose-built ERP like OnRamp, your shop can now operate like a well-oiled machine:

Which is now accessible to everyone from the office to the shop floor

So, you always know what’s running, what’s coming, and what’s a risk of falling behind

To eliminate over-ordering, reduce scrap, and keep jobs flowing

Based on facts, not gut instincts or scattered information

Keeping machines running and avoiding costly downtime

Running lean isn’t just about efficiency or trimming waste, it’s about transforming the way your entire operation thinks, performs and delivers. It now becomes a culture shift.

When your operation runs like a high-performance machine, the impact is felt in every corner of the business.

Team morale skyrockets

Your employees aren’t chasing fires, or guessing what’s next, they’re focused, confident, and in control. Less stress, more pride, and higher retention.

Customer satisfaction soars

You deliver consistently, communicate clearly, and eliminate surprises. Reliability becomes your brand, and customers will notice, and continue to value your service.

Reputation becomes your edge

You don’t become just another shop, you’re the shop that delivers on time, with precision, professionalism and outstanding quality.

Leadership gains clarity

With live data and actionable insights, you can begin to make smarter decisions, faster without second guessing or backtracking.

Efficient manufacturing is all about precision, visibility, and building a shop that can grow without breaking under pressure. This isn’t an idea or a dream, this is what happens when your operation is powered by OnRamp’s modern purpose-built ERP solution.

OnRamp is a purpose-built ERP system built by manufacturers, for manufacturers. This system was built for the realities of small and mid-sized manufacturers having real-world features that directly address the daily challenges powder coating companies deal with daily. It will give your entire organization the tools to stay on track, reduce waste, and hit deadlines with confidence.

From missed deadlines to unexpected downtime, OnRamp gives you full control over your operations so you can stop reacting and start optimizing.

OnRamp’s is built to directly address the realities of powder coating operations:

Know exactly what’s running, and what’s scheduled, and where bottlenecks are forming, no more overloading your line, or missing key steps

Stay ahead of breakdowns with automated maintenance alerts tied directly to machine usage and performance

Schedule based on actual data, not gut feel, so your line is always optimized, and jobs are completed on time

Eliminate material errors with integrated job specs, inventory management and quality control tracking

Monitor utilization, schedule preventive maintenance, and avoid costly interruptions

All departments from sales to shipping are connected and unified by one platform using the same live data, no more silos, and no more miscommunication

The days of having to manually track scheduling, inventory, job progress, and the hidden blind spots in your process are finally over. If you are serious about growing your business, keeping your customers happy, and running a lean facility, you need the tools that work as hard as you do.

Let’s talk about how OnRamp can help your coating operation run at full power.

📅 Book a call with our team or Learn more about powder coating solution

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.