Author: Ian Church in: Nesting

When your laser or plasma table becomes the bottleneck, everything else in the plant feels the strain. Most shops try to fix it with better nesting software, but the real breakthrough happens when nesting is tied directly into the way you plan and run production. These are just a few examples of frustrations with nesting that I’ve heard from owners, operators, and everyone in between throughout my career in manufacturing:

“Our ERP doesn’t talk to our nesting software.”

“We have no idea if nests are tied to the right revision.”

“Scheduling is a nightmare because nesting is done in a silo.”

“We lose material traceability once parts hit the nest.”

“Purchasing buys based on estimates, not actual nesting consumption.”

“Operators reuse old nests because the ERP doesn’t generate a clean plan.”

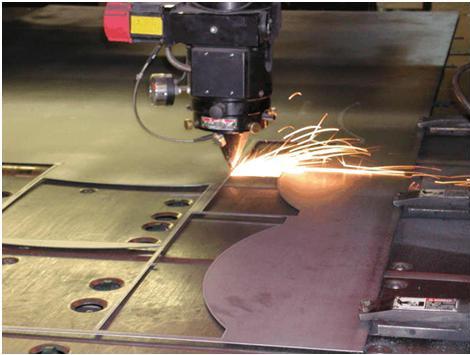

Material optimization, cutting efficiency, and production coordination all depend on having a great CNC nesting solution for laser and plasma work centers.

Most fabrication shops share the same pain. The laser or plasma table becomes the heartbeat of the entire plant. When it runs well, everything flows. When it does not, the whole schedule slips.

The root cause is almost always a visibility problem. Nesting happens in one place. Scheduling happens in another. Operators work from tribal knowledge. Engineering changes arrive late. Priorities shift. Inventory is not in sync with the cut plan.

The result is a laser or plasma machine that becomes unpredictable. Parts are cut out of sequence. Expedites pile up. Operators rerun old nests because it is faster than chasing down the right ones. Nobody actually knows how much material was consumed until someone updates a spreadsheet.

This is the moment where many shops start looking at CNC nesting software. But the truth is simple. Nesting software alone will not fix a bottleneck. What fixes the bottleneck is integrated nesting that connects the nest to the plan, the inventory, the revision, and the floor.

Here is how that transformation works.

Shops commonly describe their current workflow like this:

Programming generates nests from job packets.

Those nests live in a folder on the server.

The schedule is built in Excel or inside the ERP.

Operators decide which nests to run based on what looks correct.

Material consumption gets updated later when someone remembers.

The nesting tool technically works. The laser technically runs. Yet the shop cannot predict throughput because the plan and the floor are never aligned.

If your bottleneck machine is unpredictable, your entire plant is unpredictable.

Integrated nesting does one critical thing. It brings nesting into the same workflow as scheduling, inventory, costing, and revision control. When the nest is connected to the plan, the bottleneck becomes stable.

Here is what that looks like in practice.

Instead of being loose files in a folder, each nest is a defined production step.

Planners can see:

Which nests are ready

Which jobs are inside each nest

How long they will run

Which machine they belong to

How they affect downstream operations

When nests are part of the actual schedule, the laser becomes predictable.

In a job shop, the priority list changes daily.

With integrated nesting:

Planners can re-sequence work

The system identifies which nests need regeneration

Operators always run the current, approved version

No more cutting outdated nests. No more wasted material. No more scrambling.

Operators are not schedulers. They should not have to decide which nest to run.

Integrated nesting tells them:

Run nest 47

From material lot ABC

For these work orders

Using this revision

This removes one of the biggest sources of variation in bottleneck performance: operator guesswork.

Standalone nesting creates a disconnect between the cut plan and inventory.

With integrated nesting:

Sheets and remnants are reserved automatically

Material usage is posted when the nest is completed

Purchasing buys based on actual consumption

Remnants are tracked and reused

For a high-velocity machine, accurate material flow is everything.

Running the wrong revision is deadly at the laser.

Integrated nesting prevents it by linking every part in the nest to the correct drawing and routing.

If engineering updates a revision, the system knows.

The nest updates automatically.

The operator cannot run the wrong file.

Predictability starts with correct data.

Once nests live inside the same system as costing and scheduling, you gain real metrics:

Planned vs actual run time

Nesting efficiency

Material yield

Scrap rate

Machine utilization

These metrics let you tune the bottleneck instead of chasing it.

When nesting is integrated, the laser stops being a mystery. It becomes the most predictable work center in the plant.

You get:

A stable, repeatable cut plan

Consistent loading and run times

Faster response to priority changes

Reduced scrap

Fewer schedule fires

Real data for improvement

Your bottleneck becomes a lever, not a liability.

This transformation is especially valuable for:

High mix, short run shops

Plants with one or two critical lasers or plasma tables

Scheduling teams drowning in constant reprioritization

Shops losing money on scrap and rework

Manufacturers struggling with traceability or outdated revisions

If your laser or plasma machine drives your entire schedule, integrated nesting will give your plant the stability it has been missing.

When you step back, the pattern is simple. Bottleneck machines become predictable when nesting is no longer a standalone task but a connected part of how the plant runs. OnRamp brings nesting, scheduling, inventory, revisions, costing, and execution into one workflow so your laser or plasma table stops operating on an island. By integrating nesting directly into your manufacturing ERP, you replace guesswork with clarity and build a cut plan the entire team can trust. The result is a work center that runs with consistency, supports the rest of your schedule, and finally performs the way you always hoped it could when you invested in the machine in the first place.

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.