Author: Ian Church in: Management

Painting and Coating

Most manufacturers track data and metrics but miss the full story behind First Pass Yield, Rework, and Line Speed, critical finishing and coating KPIs. You likely have data scattered or outdated, leaving gaps in your production management. Using a dashboard designed for your shop lets you track your finishing and coating KPI’s, capture real-time insights and spot issues before they cost you. In this post, you’ll see how OnRamp Solutions helps you set clear targets and track these critical metrics with ease.

“KPI” has become a buzzword in many walks of life, including manufacturing and software. In our connected world, we have never had more access to data. The mountains of data we are collecting and storing are useless unless you do something with it. So how do we make use of it? We decide what’s important to the short and long-term success of the operation we are collecting data on, we define metrics that will indicate whether we are on track for achieving our desired outcomes, and we track and manage to them. And there you have your key performance indicators. For a finishing or coating shop, there are some unique KPIs like First Pass Yield (FPY), Rework, and Line Speed that are critical to be measuring and monitoring. They are great KPI’s for showing how well your production is performing and where improvements are needed.

FPY measures the percentage of products that meet quality standards without needing rework. A higher FPY means less waste and more efficiency. Imagine producing ten items, and only eight pass quality checks on the first try. Your FPY would be 80%. Tracking this can help you pinpoint problem areas in the production line.

Improving FPY reduces costs and boosts customer satisfaction. By identifying issues early, you save time and resources. This also means fewer customer complaints and returns. If you’re looking for a deeper dive, read more here.

Rework is costly and time-consuming (duh). You need to minimize (or eliminate!) rework if you want to run a world-class operation. But as with any problem-solving challenge, the first thing you need to do is a root-cause analysis. Dive deep on the problem, make it an area of focus. Are certain materials causing more issues? Is a particular machine frequently malfunctioning?

Once you’ve identified the causes, start solutioning. And do the math. Even small adjustments can make big impacts over the course of time. Most manufacturers don’t realize how small changes can significantly impact their bottom line. Focusing on rework reduction can result in substantial savings over time.

For more insights on FPY and minimizing rework, check out this detailed guide.

Line Speed measures how quickly you produce items. Faster isn’t always better if quality suffers. It’s about finding the right balance between speed and quality. Analyze your machinery and workforce efficiency. Are there bottlenecks slowing things down?

As with rework, steps 1 and 2 are always establishing and monitoring the KPI, and then doing the analysis. Without understanding your current state (and the problem(s)), you can’t fix anything.

Optimizing your Line Speed KPI obviously boosts overall productivity. You’ll create more products in less time without sacrificing quality. This is crucial for meeting customer demands and staying competitive. An optimized line speed enhances your ability to deliver on time, every time.

Now that we’ve explored key KPIs, let’s dive into how you can effectively capture and analyze them. A robust system is critical for accurate tracking.

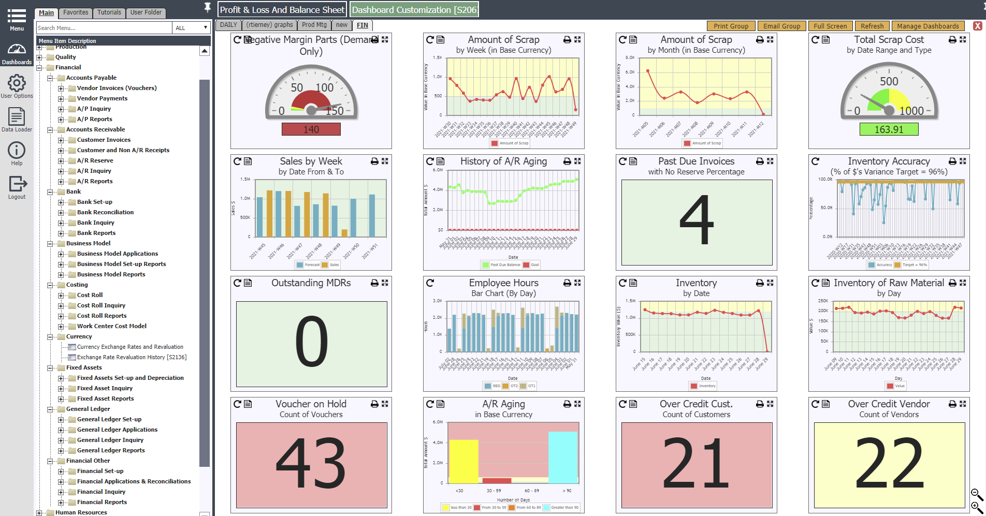

A KPI dashboard centralizes your data, making it easier to monitor. It provides real-time updates, helping you spot issues before they escalate. Imagine having all your KPIs in one place, accessible at a glance. This is not just convenient but essential for decision-making.

With a dashboard, you can set specific targets and track progress over time. This ensures you stay on course to meet your production goals. It’s your go-to tool for maintaining efficiency and improving operations. Learn more about building an effective KPI dashboard.

OnRamp Solutions offers real-time insights, making it easier to adapt to changes. Immediate access to data allows for quick adjustments, minimizing downtime. This proactive approach is crucial for maintaining a smooth production flow.

Real-time insights also foster better communication across departments. Everyone stays informed, and issues are addressed quickly. This collaborative environment leads to more efficient processes and improved outcomes.

An ERP system streamlines operations by integrating all your data into a single platform. This eliminates data silos, enhancing visibility across the board. By having all information in one place, you can make better, data-driven decisions.

With an ERP, manual data entry becomes a thing of the past. Automation reduces errors and frees up your team to focus on more strategic tasks. This increased efficiency leads to higher productivity and better resource management.

To achieve manufacturing excellence, you need to leverage the right tools and strategies. OnRamp Solutions provides tailored solutions for industry challenges.

Operational excellence is about doing more with less. OnRamp helps you achieve this by offering solutions that streamline processes and reduce waste. By focusing on key KPIs, you can drive continuous improvement in your operations.

OnRamp’s tools help you maintain high standards and meet customer demands consistently. This not only boosts your reputation but also strengthens customer relationships.

Every manufacturer faces unique challenges. OnRamp tailors its solutions to fit your specific needs. Whether it’s improving FPY, reducing rework, or optimizing line speed, OnRamp has you covered.

These tailored solutions ensure you get the most out of your resources. By addressing your specific pain points, you can enhance efficiency and boost profitability. OnRamp’s expertise and support are your keys to success in the competitive manufacturing landscape.

By focusing on these strategies and insights, you can transform your manufacturing operations and achieve greater success. Embrace these tools and take your production to the next level.

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.