Author: Andrew Holmes in: Maintenance

Unplanned downtime destroys your schedule. You schedule preventive maintenance. You follow the plan. Breakdowns still happen. Overall productivity is still not optimized.

The problem isn’t your maintenance schedule. The problem is your maintenance lives in a separate system.

Production doesn’t see scheduled maintenance. Schedulers book jobs on machines due for service. Maintenance waits on parts purchasing never ordered. Your preventive strategy becomes reactive.

Integrated preventive maintenance solves this. Connect maintenance planning directly with your ERP and MRP systems.

Last week I wrote about why preventive maintenance is critical to the efficient operation of a finishing and coating shop. This entry is all about how to leverage the right technology to make it easy and effective.

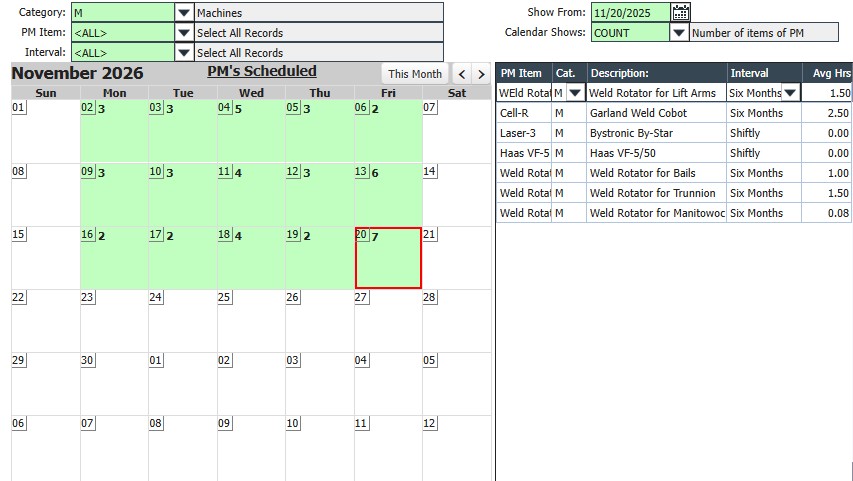

Preventive maintenance ERP integration eliminates scheduling conflicts. When maintenance and production share the same system, the software blocks out machines due for service. Production schedulers see maintenance windows in real time. Maintenance teams plan work around production priorities.

Both teams work from the same data. Both teams make coordinated decisions.

Manufacturing ERP integration treats maintenance as inventory demand. Your MRP system includes spare parts, lubricants, filters, and consumables in purchasing plans.

You avoid emergency orders for missing parts. You avoid postponed maintenance because a component wasn’t in stock. Everything needed for scheduled work gets planned and stocked.

Industrial ovens in coating and finishing operations need regular calibration, heating element inspection, and exhaust system maintenance. Skip a PM cycle and you get product defects, rejected batches, or line shutdowns.

When oven maintenance schedules live in your ERP system alongside production schedules, you plan coating runs around maintenance windows. The system reorders parts like thermocouples and heating elements based on replacement cycles. Maintenance history tracks performance trends and catches problems before they cause downtime.

Integrated preventive maintenance makes uptime predictable. Your production schedules stay reliable. Equipment runs within spec and quality improves. Scrap rates drop. Lead times stay consistent. Preventive maintenance without an integrated schedule is not really proactive, it’s reactive. And a reactive preventive maintenance schedule sort of… defeats the purpose. Sure, you’re still servicing your machines on a schedule, but if you’re not optimizing uptime with synchronized schedules, you’re still not getting the most our of your shop or plant.

When maintenance work orders, labor hours, and materials flow through your preventive maintenance ERP system, you see every dollar. You track:

Total maintenance cost per asset

Frequency and duration of downtime

Impact on production margins

Cost trends showing when repair becomes more expensive than replacement

This data drives better capital decisions. Repair, replace, or redesign based on performance history, not guesses.

Metalworking, machinery production, and finishing shops need equipment reliability. Integrating preventive maintenance with ERP and MRP keeps production efficient, predictable, and profitable.

OnRamp’s integrated Maintenance solution connects your preventive maintenance plans with production scheduling and material planning. Downtime becomes part of the plan, not a surprise.

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.