Author: Andrew Jolliffe in: Painting and Coating

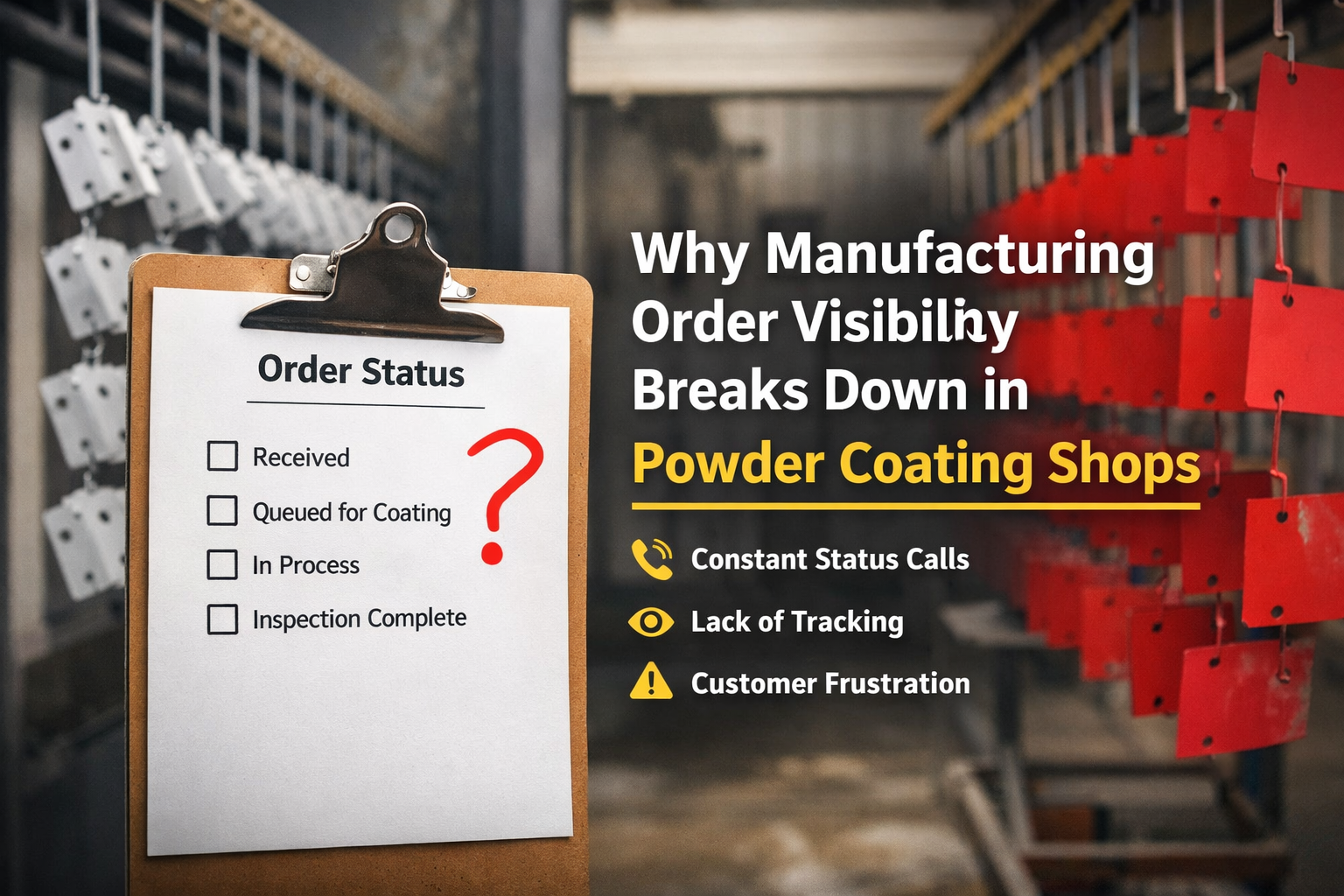

Manufacturing order visibility often feels clear during quoting. Lead times align. Color requirements look simple. Expectations feel set. Then parts arrive at your powder coating shop, and visibility drops fast.

From the customer’s view, powder coating turns into a black box. Status updates slow. Timelines feel vague. Calls and emails increase. Inside your shop, work moves forward. Outside your shop, customers feel disconnected.

This gap drains time and trust.

Once parts ship to your powder coating operation, customers lose physical control. Visibility becomes their only signal. When updates stop, concern grows.

Most frustration comes from silence, not delay.

The breakdown usually starts here:

Job status lives on whiteboards or paper travelers

Work queues form around color batching

Parts wait staged for the next run

Cure and inspection steps add time without clear markers

Customer service lacks live access to the floor

From your side, this is normal powder coating flow. From the customer’s side, it looks like nothing is happening.

Powder coating depends on batching. Color changes drive efficiency. Ovens dictate pacing. Racking density shapes throughput.

Jobs do not move in straight lines.

Common powder coating realities customers rarely see:

Jobs wait to align with color runs

Lower volume colors move behind high volume batches

Rework restarts racking, coating, and cure

Film thickness and adhesion checks pause release

Documentation review delays shipment approval

These steps protect quality. Without visibility, customers assume delay or neglect.

Every status request pulls attention off the floor. Supervisors stop planning. Leads walk the line. Customer service hunts for answers.

Reactive updates create hidden costs:

Interrupted production flow

Slower scheduling decisions

Inconsistent answers to customers

Escalations tied to missed expectations

Discounts used to preserve relationships

Over time, customers learn to call early and often. Silence trains behavior.

Order visibility does not mean constant updates. It means shared understanding.

Strong visibility answers a few clear questions:

Were my parts received and verified

Which stage of the powder coating process is next

Is the job queued, in process, or under inspection

Did anything change since the last update

When should I expect the next milestone

When customers see honest status stages, calls drop.

You do not need complex tracking. You need consistent signals tied to real workflow stages.

Start with clear status milestones:

Parts received and staged

Queued for color run

Coated and cured

Inspection complete

Shipped

Each status reflects how powder coating actually works. No false precision. No forced timelines.

Next, push updates instead of waiting for questions. Automated notices at receipt, start of coating, and shipment prevent most follow-ups.

Then, communicate uncertainty early. If a job misses a color run or enters rework, say so when it happens. Customers respond better to early clarity than late apologies.

Visibility breaks when information fragments. Whiteboards, spreadsheets, and memory do not scale.

A shared source of truth keeps everyone aligned:

Supervisors avoid constant interruptions

Customer service answers without chasing the floor

Sales sets accurate expectations

Customers check status without calling

Alignment inside the shop shows up as confidence outside the shop.

Many powder coating shops reach a point where effort, not intent, blocks transparency. People know the status. They lack a clean way to share it.

This is where systemized operations change the equation.

When production status updates in real time as work moves through racking, coating, cure, and inspection, visibility becomes automatic. Customers see progress without asking. Internal teams work from the same information.

OnRamp supports this by tying powder coating workflows to live job status, customer access, and optional automated notifications. The goal is not more communication. The goal is fewer interruptions and fewer surprises.

Clear order visibility reshapes customer behavior. When customers understand where their job sits, they stop guessing. When updates arrive without chasing, trust grows.

Powder coating shops with strong visibility experience:

Fewer status calls

Fewer escalations

Less expediting

Fewer price concessions

Stronger long-term accounts

Transparency stops feeling like overhead. It becomes part of how professional coating operations scale.

Customers do not expect perfection. They expect clarity.

They want to know:

You received their parts

You know where the job stands

You will speak up when something changes

When you provide that, powder coating stops feeling like a black box. It starts feeling predictable, controlled, and reliable.

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.