Author: Ian Church in: Quality Management

OEM customers expect proof before trust. PPAP documentation provides that proof. When PPAP requirements are not met or your program breaks down, shipments stall, chargebacks follow, and relationships suffer.

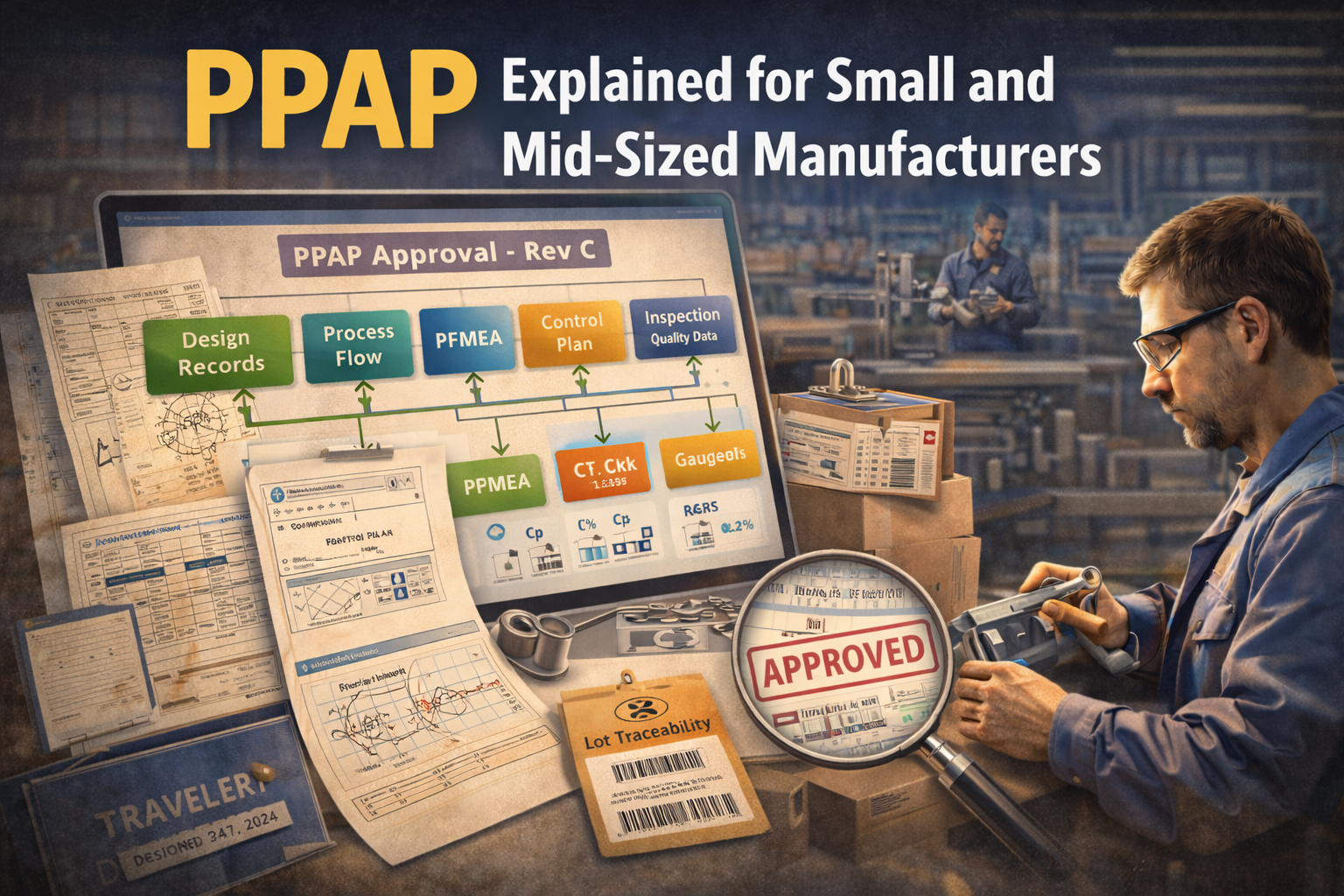

PPAP stands for Production Part Approval Process. At its core, PPAP shows your customer how your shop turns a drawing into repeatable production output.

An approved PPAP demonstrates three essentials:

You understand the drawing and customer requirements

Your process produces parts within specification

Your process remains stable at production volume

Once approved, PPAP reduces oversight and inspection. Without approval, customers increase scrutiny and restrict shipments.

Customers usually request PPAP when risk increases. These moments signal a change from proven conditions to something new.

PPAP typically becomes mandatory during:

New part launches or onboarding a new customer

Drawing revisions or engineering changes

New tooling, fixtures, or process steps

New machines, lines, or facilities

Production restarts after extended downtime

Contractual or customer-specific requirements

Shipping parts during these events without approval exposes your shop to rejects, chargebacks, and emergency escalations.

Customers request PPAP, but their real goal involves predictability. They want confidence that production runs without surprises.

During review, buyers focus on signals such as:

Process stability over time

Reliable measurement systems

Tight revision control

Clear material and lot traceability

Defined reactions when results drift

They notice rushed submissions. They notice reused templates. They notice gaps between documents and shop floor behavior.

PPAP can get complicated fast. There are 5 levels, each more stringent than the last. Most OEMs request PPAP Level 3. While PPAP includes many elements, customers concentrate on a core set that reflects real process discipline.

These define the baseline. Use the current drawing revision only. Any mismatch invalidates the entire submission.

This explains how work moves through your shop. Customers look for missing steps, rework loops, and uncontrolled handoffs.

This shows how you think about failure. Real failure modes and controls build trust. Generic entries erode it.

This defines how you monitor the process. Inspection points must align with real operations, not idealized workflows.

This proves your gages produce repeatable results. Poor measurement undermines all downstream data.

These measurements must come from true production parts. Special setups raise questions during review.

These records confirm material, coating, and testing meet specification. Tie results to specific lots.

Capability data such as Cp and Cpk show stability during production runs. Consistency matters more than perfection.

This document represents your commitment. Customers treat it as your formal acceptance of responsibility.

Audit findings and customer feedback reveal consistent breakdowns. These failures usually reflect process disconnects rather than technical gaps.

Common issues include:

PPAP documents spread across spreadsheets and email

Control plans disconnected from routings

Inspection requirements ignored during production

Revision mismatches between quality and operations

Rebuilding PPAP packages after customer complaints

Each issue points to weak linkage between systems and execution.

Manufacturers of all sizes typically understand PPAP requirements. The challenge lies in sustaining them during daily production pressure.

PPAP becomes difficult when:

Quality data sits outside normal workflows

Inspections live outside work orders

Revisions fail to propagate automatically

Tribal knowledge replaces documented process

In this environment, PPAP turns reactive. Teams rebuild packages under pressure instead of maintaining them continuously.

Strong PPAP programs blend into daily operations. They rely on structure rather than heroics.

Successful shops share these traits:

One source of truth for drawings and revisions

Routings aligned with inspection requirements

Production data feeding capability analysis

Rapid access during audits and customer reviews

Clear linkage between PPAP, quality, and shipping

PPAP becomes routine output rather than a special project.

PPAP performance depends on connection across functions. Disconnected systems force manual work and increase risk.

Low-cost, high-impact programs materialize when your ERP integrates:

BOMs and routings

Quality inspections and SPC

Revision control

Lot and serial traceability

Document management

PPAP aligns naturally with production. Submissions improve. Audits accelerate. Customer confidence grows.

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.