Author: Andrew Jolliffe in: Painting and Coating

Quality Management

Powder coating problems show up fast. Film builds drift. Colors vary. Parts fail inspection. Scrap and rework follow. You feel it in throughput, labor, and customer complaints. Powder coating quality control improves when you focus on three quality tools built for process discipline.

Statistical Process Control, or SPC, uses real-time data to monitor how your powder coating process behaves over time. You track key measures like coating thickness to spot trends and shifts early, before variation turns into scrap or rework. Ultimately, SPC helps you control variation on the coating line before defects stack up.

Film thickness drifting across a shift.

Transfer efficiency changing by gun setup.

Cure issues tied to oven temperature swings.

Coating thickness.

Part temperature before cure.

Line speed and dwell time.

Measure thickness at defined intervals.

Plot results on a control chart.

Act when trends or shifts appear.

You stop sorting parts at final inspection.

You catch gun wear, grounding issues, and setup drift early.

You stabilize quality across operators and shifts.

Start with the metric tied to the most scrap or rework.

Measurement Systems Analysis, or MSA, checks whether your coating thickness measurements support good decisions. You evaluate gauge accuracy and operator consistency so inspection data reflects the process, not noise from the measurement method. If thickness measurements vary, your decisions fail. Ultimately, MSA validates your inspection process.

Inconsistent use of magnetic or eddy current gauges.

Operator technique affecting readings.

Worn or uncalibrated thickness meters.

Repeatability by measuring the same part multiple times.

Reproducibility by comparing operators.

Gauge variation versus process variation.

You avoid rejecting good parts.

You avoid shipping under coated parts.

You remove arguments over inspection results.

Fix the measurement system before adjusting guns, recipes, or line speed.

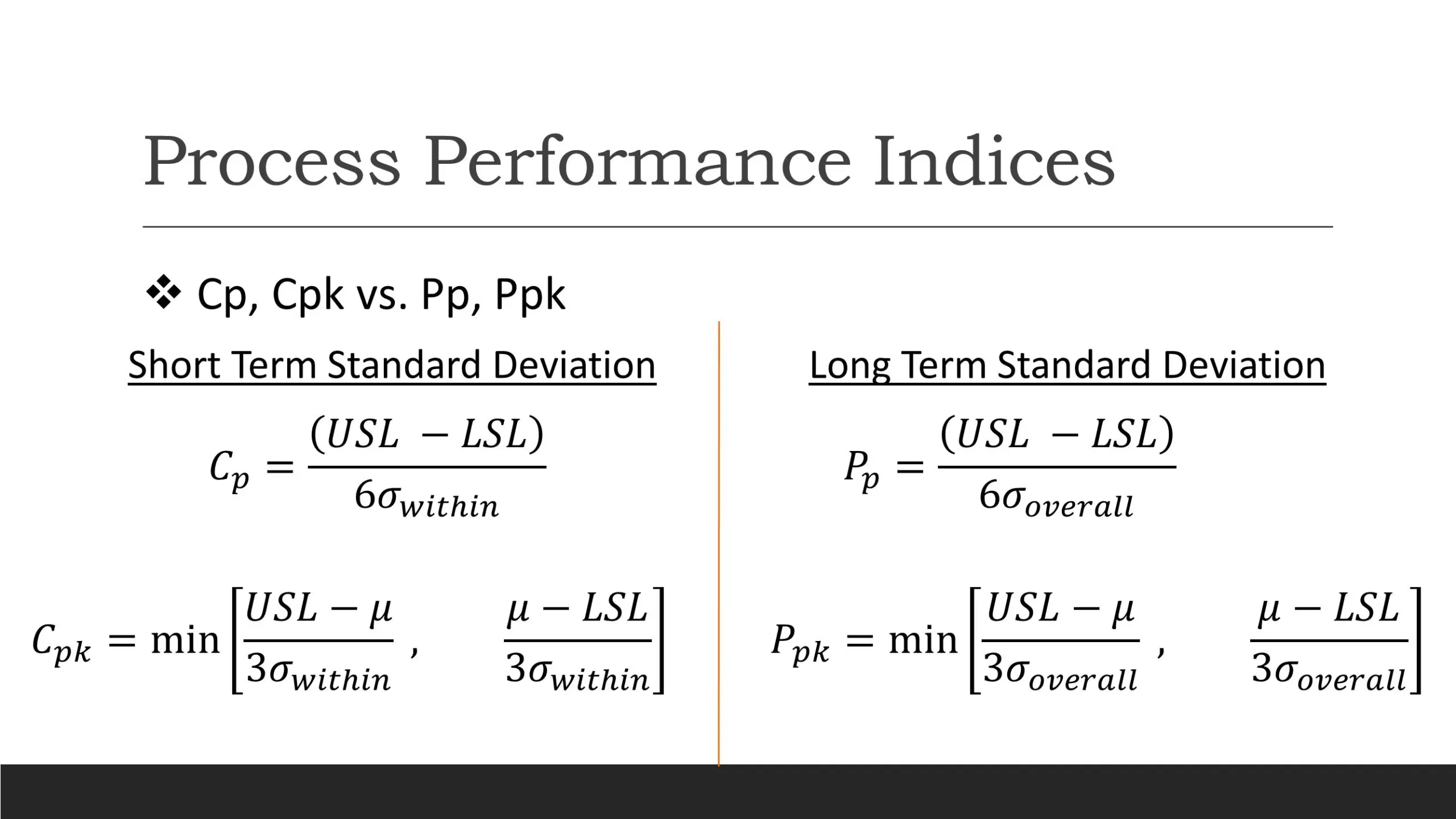

Process capability measures how well your powder coating process meets thickness tolerances over time. It shows whether variation and centering allow the process to stay within spec or if defects remain unavoidable even when the line runs stable. Ultimately, capability shows whether your coating process meets thickness requirements consistently.

Does the process stay within thickness tolerance.

How centered the process runs.

How much risk exists before defects appear.

Cp and Cpk for stable, short term runs.

Pp and Ppk for long term performance.

Tight thickness windows leave little margin.

Low capability leads to scrap, rework, and chargebacks.

Capability data supports realistic quotes and process limits.

Run capability analyses only after SPC shows a stable process.

The best approach to powder coating quality control is to use each of these tools in sequence:

Validate thickness measurements with MSA.

Control variation with SPC.

Confirm performance with capability analysis.

For anyone just getting started, it likely feels overwhelming, but skipping steps wastes time and hides real causes of defects.

This is how to apply these tools on your powder coating line this month:

Pick one coating thickness spec driving scrap.

Verify your thickness gauge and inspection method.

Set up a basic SPC chart.

Review results daily with operators.

Run capability once the process stabilizes.

This approach gets you started fast and it will make a difference. It reduces variation, improves consistency, and protects margin in powder coating operations.

This blog represents a ten thousand foot overview of these three critical tools for quality management in powder coating operations. If you’re looking for a deeper dive on any of these tools, we’ve found some great resources:

Don’t put it off; get started with these tools today, one small step at a time!

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.