Author: Ian Church in: Implementations

Manufacturers know that EDI is the price of doing business with major customers. If you supply into automotive, heavy equipment, consumer goods, or metalworking, you do not get to choose whether you use EDI. Your customers tell you which documents to send and how they must be formatted.

The real frustration is this: most ERP vendors treat EDI as a custom project. Every trading partner becomes a one-off build. Every customer update becomes a small emergency. Every failed map becomes a support ticket. This is why so many manufacturers call EDI the most painful part of ERP implementation. The problem is not EDI itself. The problem is that most vendors never productize it.

This article covers what product-ized EDI and EDI automation actually means, why it matters, and how it protects small and mid-sized manufacturers from the headaches they know too well.

But first, if you’re looking for more general information on EDI in manufacturing, check out this explainer.

Most ERP vendors do not own EDI. They outsource it to a separate EDI provider. That provider then builds custom maps for each trading partner.

This creates three predictable problems:

If there is an error, each vendor blames the other. The ERP vendor says the EDI provider mapped it incorrectly. The EDI provider says the ERP export was wrong. Meanwhile, your shipping team cannot send the ASN and the truck is waiting.

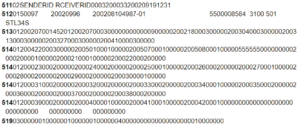

Every OEM uses the same X12 standards in theory, but every one of them interprets the rules differently. That means:

Custom 850 formats

Custom 856 (ASN) structures

Custom invoice rules

Custom changes at random intervals

Custom means slow, expensive, and fragile.

OEMs frequently update their requirements. With custom EDI, every update turns into a new bill.

The result is an integration that never feels stable.

Product-ized EDI is the opposite of custom. It means the vendor treats EDI as a core product, not a bolt-on.

A product-ized EDI approach includes:

Your vendor already knows the format for your customer because it is in the product. There is no “mapping project.” There is no custom development. It just works.

When your customer changes the 856 or adjusts how they send forecast schedules, your vendor updates the map as part of standard product maintenance. You do not pay for this. You do not manage it. You do not coordinate vendors.

Product-ized means that:

Inbound POs auto-create sales orders

Forecasts drop into planning and MRP cleanly

ASNs follow your shipping processes

Invoices follow customer rules

Exceptions are flagged with real context

Everything is designed to work together because the vendor built it together. True EDI automation!

EDI only solves half the problem. The other half is customer-required documents, including:

Pallet labels

Packing slips

Carton labels

Invoices

Shipping documents

Product-ized EDI includes product-ized documents. These formats are built into the ERP and maintained the same way maps are maintained.

When EDI is part of the product, your team does not have to track down whether the issue is in the ERP or the EDI provider. Everything is supported and owned by a single team.

If you supply to OEMs, EDI is not optional. It is a revenue requirement. If EDI breaks, you cannot ship. If labels or ASNs fail, you get chargebacks. If forecasts are wrong, MRP explodes.

Manufacturers should demand product-ized EDI because it solves the root cause of every one of these problems.

Most ERP implementations drag on because EDI is late. Prebuilt maps remove this bottleneck.

You are not paying for mapping, remapping, customizations, or EDI vendor coordination. The integration is already part of the solution.

Because the maps, labels, and documents match what your customers expect.

Forecasts update correctly. ASNs match labels. Invoices follow the correct rules. Shipping does not get stuck chasing formatting mistakes.

When EDI is product-ized, updates are handled by the vendor. Your team does not scramble every time a customer changes something.

Manufacturers do not want to “build their EDI.” They want EDI that works on day one and continues to work without custom development, vendor coordination, or constant rework.

Product-ized EDI is exactly that. It is predictable, stable, and maintained by the people who built the ERP. For small and mid-sized manufacturers, this approach removes the single biggest source of risk in ERP projects.

If you want to turn EDI from a project into a predictable part of your operations, product-ized EDI is the approach to demand.

Our list of supported EDI mappings is growing monthly. It is likely that we already support many of your customers and vendors. And don’t fret if we don’t. Our approach means that we’ll add yours to our product as part of your implementation using our simple EDI setup wizard. And then we’ll take it from there, forever.

Curious whether your customers and vendors are already part of OnRamp’s product-ized EDI formats? Contact us to find out.

For more information about how OnRamp ERP software can add value to your business fill in the contact form below. A member of our support team will contact you within 1 business day to discuss any questions you have.

Start the collaboration with us while figuring out the best solution based on your needs.

Has your business outgrown a patchwork of disconnected systems? This checklist helps you assess readiness, identify gaps, and prepare for a smooth transition.