OnRamp ERP does more than just send work orders to your nesting software. It automates, tracks, and optimizes every step of your nesting workflow, from cut planning to material usage, so you reduce waste, improve throughput, and remove bottlenecks from the shop floor.

Maximize Efficiency with OnRamp’s ERP Nesting Software Integration

Manufacturing success starts with optimizing how you cut raw materials. OnRamp ERP’s nesting software for manufacturing takes the guesswork out of material utilization, seamlessly connecting with top nesting software like SigmaNEST to eliminate waste, reduce manual entry, and accelerate production. With real-time demand tracking and automated nesting workflows, OnRamp ensures you make the most of every sheet, plate, and raw material, giving your business a powerful advantage over competitors in an industry where efficiency, precision, and cost control are key to staying ahead.

Built for the Shop Floor—Not Just the Office

Many systems like to boast about integrating with a nesting package like SigmaNEST. The traditional method is to send released work orders to the nesting software, the nesting software does what it is told to, and a nest is created. OnRamp saw things a little differently.

Our solution comes from real manufacturing experience. OnRamp ERP was born on the shop floor of Mancor Industries, a Tier 1 manufacturing group where nesting and cutting are critical to production. Mancor needed a truly integrated nesting optimization solution—and OnRamp delivered.

How OnRamp Streamlines Nesting from Start to Finish

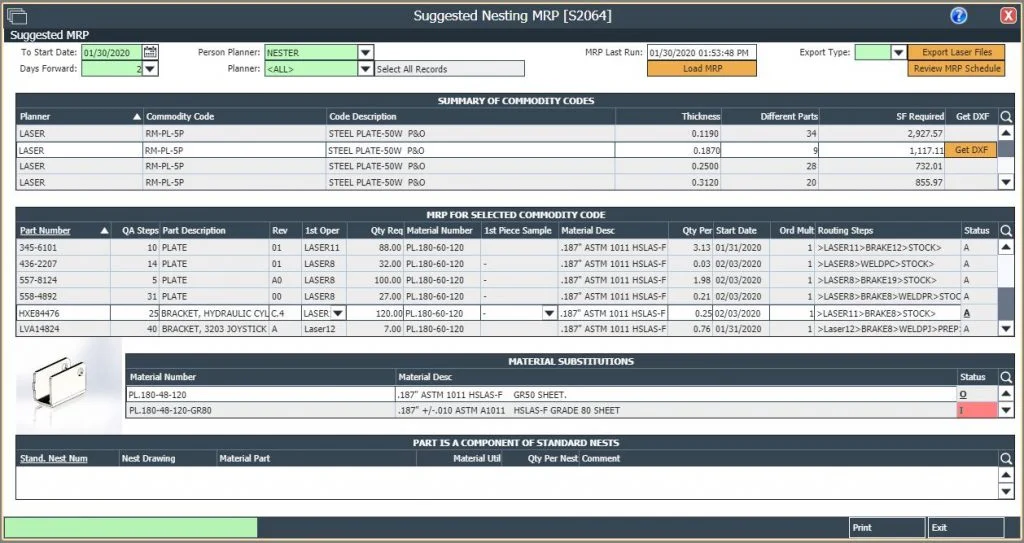

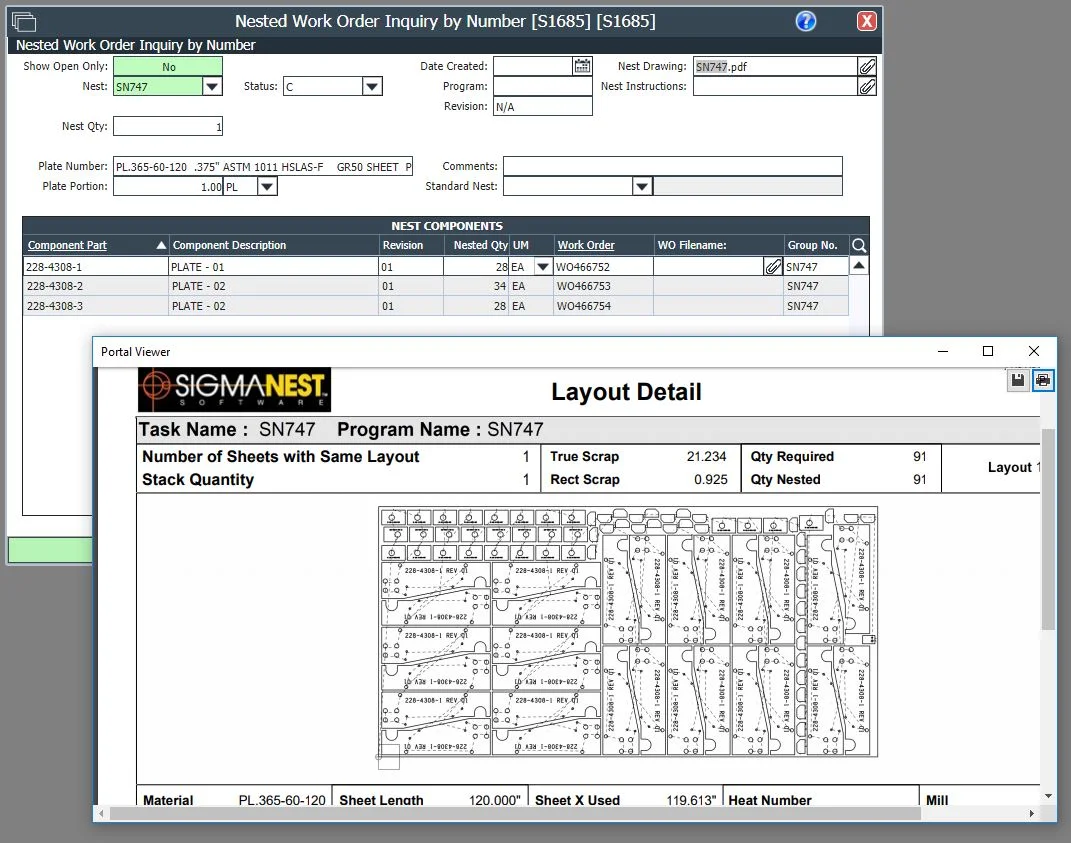

OnRamp ERP goes beyond traditional nesting integration by actively managing the entire ERP nesting integration workflow—from material demand to visual scheduling—without the guesswork.

Here’s how it works:

- Material requirements are automatically sent to your nesting software (e.g. SigmaNEST)

- The software executes nesting automation for maximum material utilization and efficiency

- Nested orders are seamlessly pushed back into OnRamp ERP

- Inside OnRamp, all nests are:

- Fully tracked and managed

- Assigned to the appropriate machines

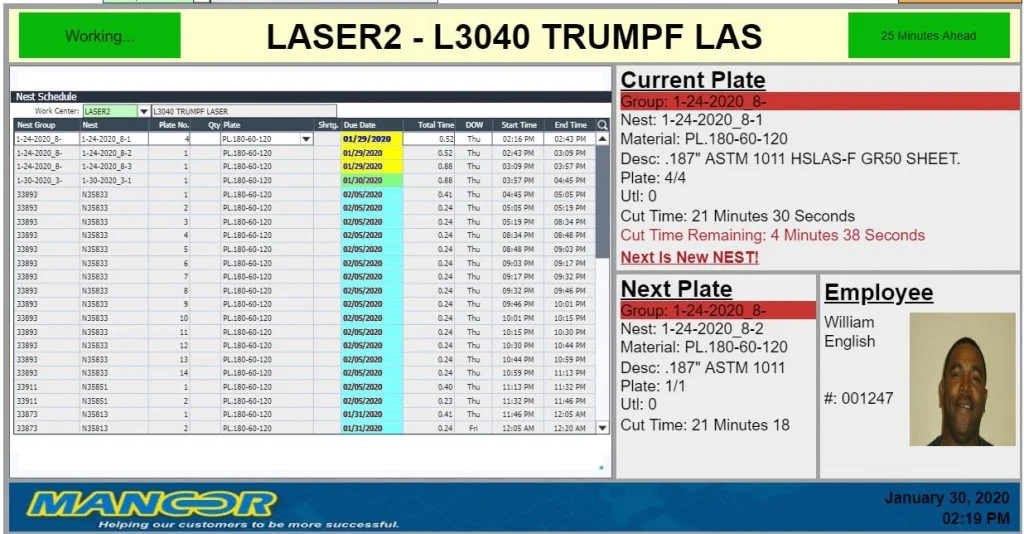

- Scheduled using a visual drag-and-drop interface

With this closed-loop integration, you can:

- Monitor nest completion times and overdue jobs

- View all nested parts in each package

- Track plate utilization and remnant usage

- Summarize demand by material grade and thickness

This system eliminates redundant data entry, improves job visibility, and reduces idle time, turning nesting into a streamlined, data-driven operation. These are the tools that any fabricator needs and are the tools our customers can’t imagine working without.

See Our ERP Nesting Software in action

Key Features of the Nesting Integration Module

Complete ERP Nesting Integration (SigmaNEST, etc.)

Visual Nest Scheduling

Remnant Usage Tracking

Nest Reporting

Demand Summaries by Material Grade & Thickness

Plate Utilization Reports

SPC (Statistical Process Control) for Cutting Operations

Real-Time Status Monitoring

Unleash the Full Power of ERP-Integrated Nesting

By fully integrating nesting with your ERP system, you remove production bottlenecks and get parts to the shop floor faster and with greater accuracy. OnRamp ERP delivers:

- No more duplicate data entry – Reduce human error and ensure the latest scheduling information is always used.

- Faster job processing – Automated nesting updates push orders to production instantly.

- Optimized material usage – Easily combine orders with the same material grade and thickness to minimize waste.

- Accurate inventory & job costing – Know exactly how much material is used for every job and maintain precise stock levels.

- Better scheduling & reduced downtime – Ensure high-priority jobs are processed efficiently while cutting idle time.

- Real-time data flow – Keep inventory figures updated and maximize efficiency with ERP-integrated material tracking.

From Bottleneck to Throughput: Real-World Results

After implementing OnRamp, our customers saw improved shop floor visibility, which allowed them to get parts through their gateways faster. Manufacturing success depends on removing bottlenecks, and with OnRamp, your cutting process won’t be one of them.

Cut Smarter, Work Faster, Stay Competitive

Manufacturing is all about efficiency, and OnRamp ERP’s nesting optimization eliminates bottlenecks, enhances visibility, and improves material utilization. By combining intelligent ERP functionality with automated nesting tools, manufacturers can achieve better coordination, reduce costs, and drive higher productivity through lean manufacturing waste reduction.

Nesting Package

CAD/CAM Integration

Real Time Machine Monitoring

Suggested Orders By Grade and Thickness